PRODUCTS

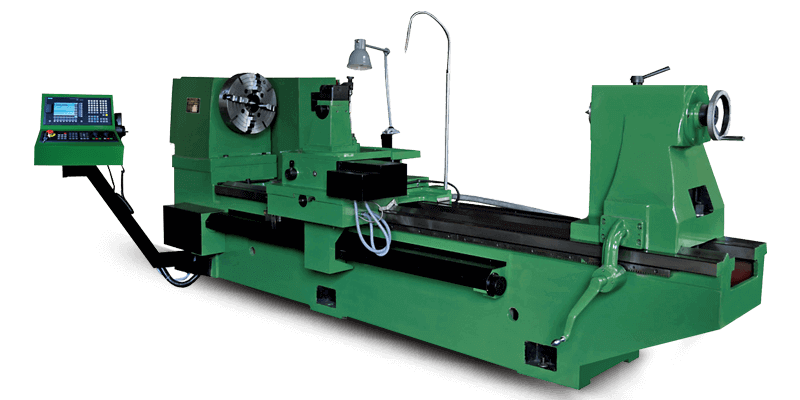

XK9350ZF CNC Roller Crescent Grooves Miller

- Available for Ni-Cr casting iron roll, S.G roll, Admite roll and H.S.steel roll.

- Notching on one groove(pass) is about 20 minutes and may less about 15 minutes.

- Lgo marking on one groove(pass) is only about 10 munutes.

- It is ideal name writing machine. A piece of marking toll is able to do marking about 100 passes.The cost for one pass marking is only about US$1.00.

- Patents designed fly cuttler notching head and marking head give fast, rigidity, stable working.

- Independent fly-cutter notching head c/w independent servo motor&drive for stable&reliable notching.

- Independent swivel marking head c/w independent servo motor&drive for fast logo marking.

- Rectangular bed with double box guide way made by resin cating, guarantee its rigidity.Beat all boat type bed and triangle guide way.

- Independent electrical cabinet built with SIEMENS,YASHIKAWA,SCHNEIDER electrical components for long working life. Better cooling, better dust-proof, better shockproof protect electrical components for long working life.

| Item | XK9350ZF |

| Max.Diameter of roller | φ100—-φ500mm |

| Max.Length of roller | 2500mm |

| Suitable for threaded steel sizes | φ6—φ50mm |

| Cutting and milling method | “Fly-cutter” cutting |

| Rotation of main milling head shaft | 0–500rpm/2.0KW |

| Min.feed unit | 0.001mm(AC servo drive) |

| Conical hole for main heard frame shaft | MT5 |

| Chuck of main head frame shaft | Φ400mm |

| CNC system | Mitsubishi digital control system,Japan |

| Power of main motor | 380V/50HZ |

| Dimension(L×W×H) | 4000×1580×1900 |

| Machine weight | 4700kg |

| Remarks | Normal Rolls,HSS Rolls, TC ring |