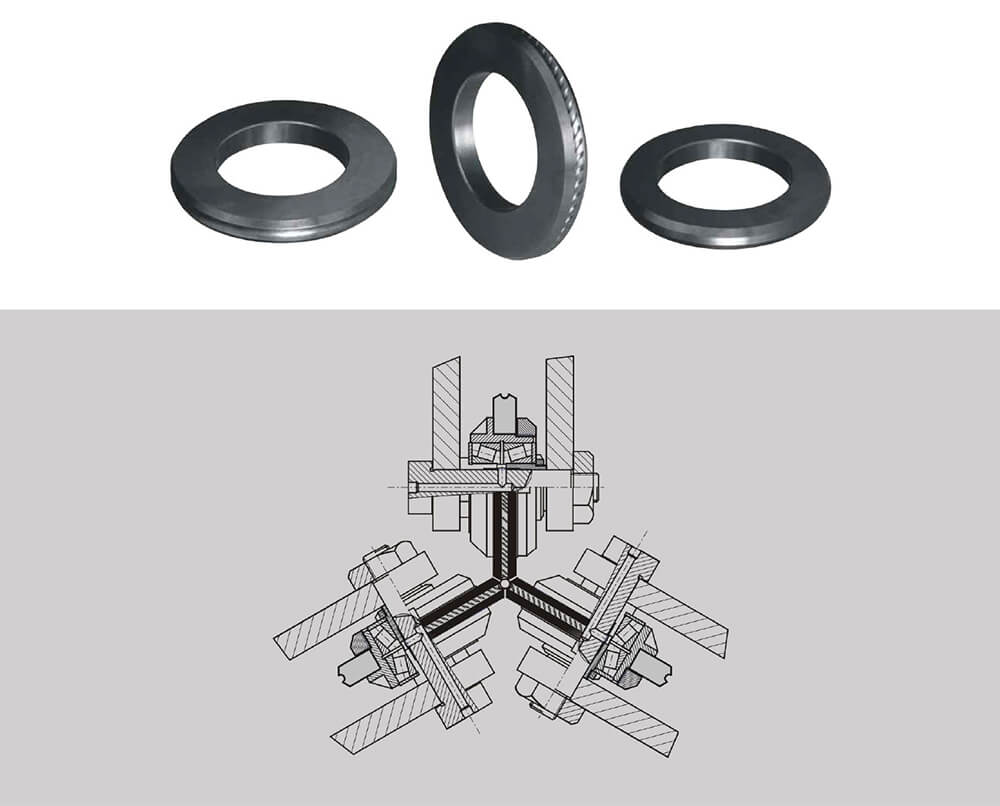

Three dimensional carbide roll rings for cold rolling of ribbed steel bars

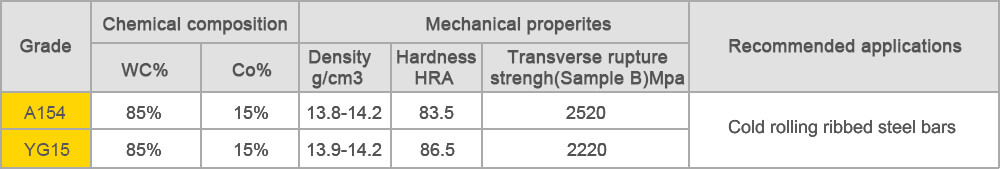

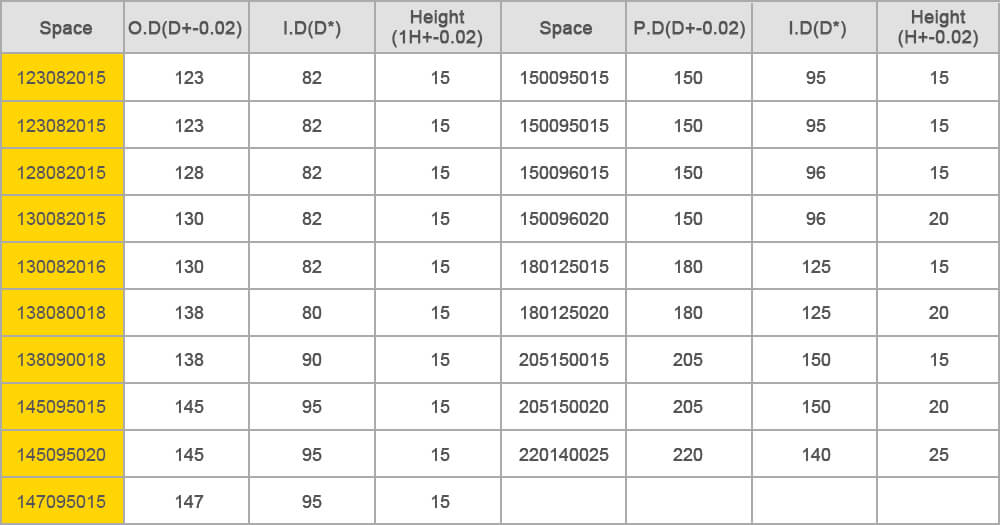

- The specifications in the table are recommended for use. We can also produce roll rings according to drawings provided by customers.

- The grooves of the roll rings can be designed and manufactured according to GB13788-2000 standard and they can also be designed based on customers’requirments and marked in a special way.

- We can supply compatible tool steel systems to customers for assisting them in modifying their mills and rolling process.

- Any compact and knock on roll rings is strictly prohibited.

- When installing the whole assembly of roll rings, the clearance of the bearings should be on the tighter side.

- The precision of rotation of the whole assembly (circular runout and end runout) should be kept within +-0.05mm.

- The fitting in of the whole assembly and the roll rings shall be a transitional fitting-in and fastened.

- The roll rings should not be cooled by water or oil water emulsion.

- The joints of the pipes in the internal cooling system should not be leaky and it is advisable that no inner cooling is applied.